University of Bolton, Deane Road, Bolton. BL3 5AB

Tel:

Email:

“At the University of Bolton, we take great pride in providing a quality, supportive learning environment for our students.”

Professor George E Holmes DL | President & Vice Chancellor

“...tutors are very supportive and you’re not just a student ID number, at this university you are an individual with a name.”

Ellisse Vernon | BSc (Hons) Adult Nursing

Back to menu

Back to menu

Study with an Off-Campus Partner

Back to menu

Back to menu

University of Bolton, why we are the right choice

Location - Bolton, Greater Manchester

22/11/2022

The advanced manufacturing and additive world is a fascinating and ever-changing landscape. With innovations constantly popping up, it's hard to keep up with all of them!

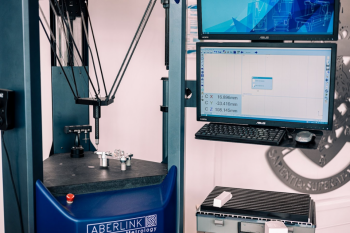

In preparation for the scheduled opening of the University of Bolton’s new Centre for Advanced Manufacturing (CfAM), we'll look at some hot topics in the field of additive manufacturing; composites technology that uses metals like aluminium or steel together with plastics for strength without having any fragility associated themselves.

Recent innovations

New technology is always exciting, but equally so are developments which propel our environmental impact into the spotlight.

The use of natural fibres for parts of race cars, seats and bodywork is a recent phenomenon of great potential for the future. The team who runs our composites workshop are experimenting with smoke and fire-retardant natural fibres for use in aircraft.

In the world of additive manufacturing, or 3D printing there is a wide variety of fast-moving technology. We will cover more of these in the future, examining different types of printing and their applications. For now, following the sustainability strand it is important to try and look at additive manufacturing, not as an expensive new process but an exciting new opportunity. This brings us onto a key point for the launch of the CfAM.

Take a look at a few of the recent innovations that in advanced and additive manufacturing:

- Generative Design

- Materials Advancement

- Self-Supporting Lattices (E.g. Gyroids)

Rob Higham, Head of the centre has a wealth of experience in the sector. From his undergraduate and postgraduate qualifications to his background at BAE Systems and his time at BMW as a diagnostics technician, the professional duties he has built up over his career to date makes him a reputable leader of the centre.

Why the Centre for Advanced Manufacturing was launched

To maximise the benefit of additive manufacturing, composites, testing and similar areas it needs to be physically and financially accessible as a process. The centre’s simple mission is to increase that accessibility.

A company having prototypes machined with 70% waste material and a cost of £5,000 per part could save over 60% in costs by switching to additive processes. Using our low cost and open approach we can provide a 3D printed equivalent from laser powder bed fusion of aluminium, same geometry but for £1,500 with no more than 3% waste.

Companies in focus

The main benefit of advanced manufacturing with the CfAM is for research and development across industries. We want to support aerospace, space, automotive, medical, dental, oil and gas and many other industries in exploration of technology for their business.

Who to talk to...

Find out how this exciting new development at the University of Bolton can help your business adapt and overcome modern manufacturing challenges with new technologies and innovative solutions!

Get in touch with the Head of Centre, Rob Higham via email at r.higham@bolton.ac.uk.